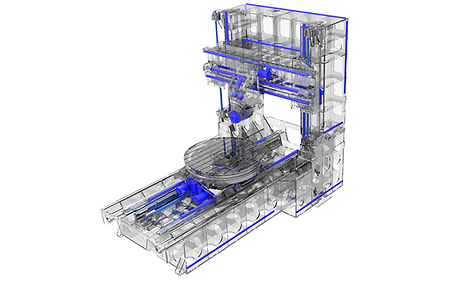

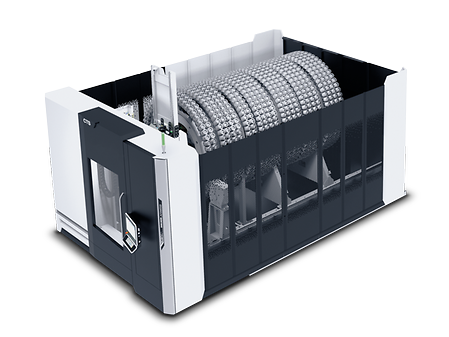

DMC 270 U (FD)

The portal series from DECKEL MAHO – more than 1,000 machines installed.

Max. X-axis stroke

2,700 mm

Max. Y-axis stroke

2,700 mm

Max. Z-axis stroke

1,600 mm

Max. workpiece diameter

3,400 mm

Max. workpiece height

1,620 mm

Max. workpiece weight

9,000 kg

Control & software alternatives

SIEMENS

HEIDENHAIN

Highlights

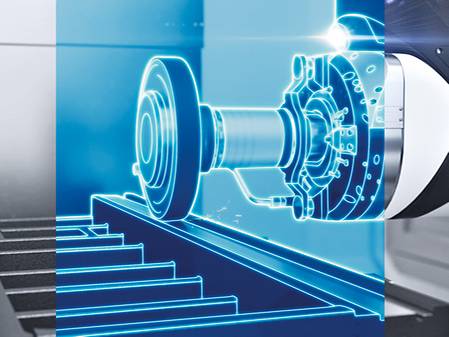

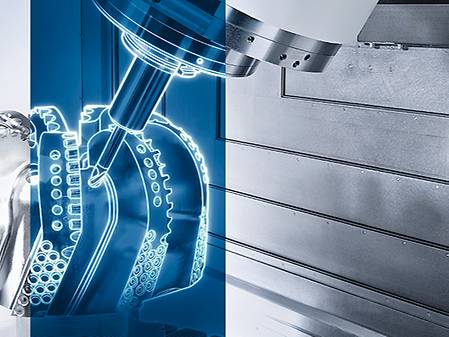

Complete machining

- Milling and turning in one setup with the DirectDrive table with a torque up to 11,000 Nm

- Best surface quality with technology integration grinding

Precision

- Maximum accuracy through water-cooled feed drive

- Band filter unit with 2,500 l as standard

- Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

Performance

- High dynamics with feed speed up to 60,000 mm/min

- Also available in mill- /turn - version

- Pallet changer for main time parallel setup as standard

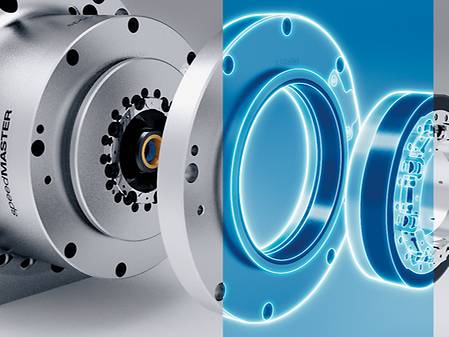

- Biggest spindle range in the market: powerMASTER motor spindle with up to 1,000 Nm and torqueMASTER gear spindle with 1,800 Nm

Efficiency

- Lower energy consumption through intelligent needs-based power units.

- Gantry design with vertically moving cross beam with hydraulic weight compensation.

- Fast innovative wheel type magazine with up to 243 tools with minimized footprint.

Application Examples

Automation

Standard automation and customised solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customised automation solution for flexible manufacturing systems:

RPS Portal

RPS 4 / 5 - Machine-integrated automation with minimum space requirement

- Unmanned shifts due to circular storage system with up to 12 pallets

- Handling of workpieces up to ø 3,400 × 1,650 mm, 10,000 kg max.

- Reduction of non-productive time due to loading and unloading during production

- Flexible production of different parts

- Pallet Master – for convenient and simple control of the automation directly via the machine control

LPP

Advanced pallet storage solution for up to 8 machines and 99 pallets

- Handling of workpieces up to ø 3,400 x 2,000 mm, 10,000 kg

- Very flexible pallet pool system with up to 8 machines, 99 pallets and 5 setup stations

- Handling of up to three different pallet sizes possible in one system (2 sizes for machine pallets and one size for material pallets)

- Control directly via DMG MORI master computer software LPS

- Integration into customer network / workflow possible

- Monitoring and management tools for all relevant areas (planning, workpieces, clamping, tools, etc.)

- Tool management system MCC-TMS

AMR 2000

Holistic automation on the shop floor

- Collaborative automation solution with free layout design

- Omnidirectional movement for minimal space requirements (turning radius 0m)

- Basis for additional tasks, e.g. B. tool handling, chip disposal, etc.

- Material transport from Euro pallets 1,200 x 800 mm

- Maximum transport weight of up to 2,000 kg

- Security based on Sick and Siemens technology

Highlights

AMR 2000 Material

- Autonomous transport of material pallets

- Load capacity up to 2000 kg

- Compact and manoeuvrable

- Integration into existing processes

AMR 2000 chips

- Autonomous transport of chip trolleys

- Automatic pick-up order from the DMGMORI master computer

- Integration into existing material processes

- Extension of machine tool autonomy over the night or weekend

- Fleet ready

AMR 2000 tool handling

- Tool identification in the standard

- Quick installation of the automation system

- Reliable technology with proven components

- Integration into existing production possible

- Max. tool dimensions ø 280 / 400 mm

- Max. tool weight 30 kg

- Transport weight 720 kg (24× 30 kg)

- Maximum number of tools: 24 pcs

CTS - Central Tool Storage

Flexible tool magazine for more than 4,000 tools

- Modular concept with step-by-step extension possibility by 360 / 240 shapes (ISO 40 / 50 recording)

- Very small footprint with only 29 m2

- Integrated tool loading solution for portal tool shuttle or with AMR 2000 tools

- Highest transport capacity through the tool - shuttle

- Transfer of up to 8 tools simultaneously

- Proven wheel magazine technology with over 1,600 units sold

Highlights

AMR 2000 Tooling

Portal tool handling

Tool transfer

AMR 2000 Tooling

- Autonomous transport of up to 24 tools between the CTS (central tool magazine) and the machine

- Quick installation of the automation system

- Integration into existing production possible

- Max. tool dimensions ø 280 / 650 mm

- Max. tool weight 30 kg

- transport weight 720 kg (24 × 30 kg)

Control & Software

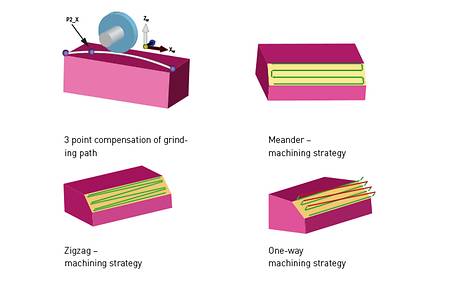

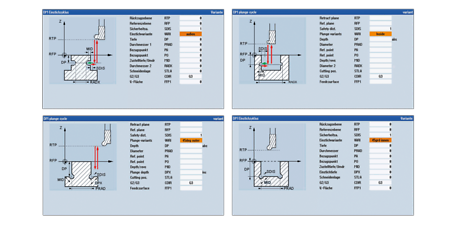

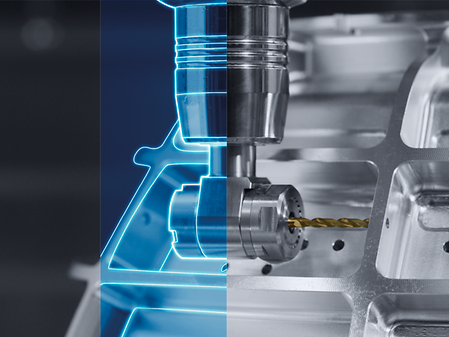

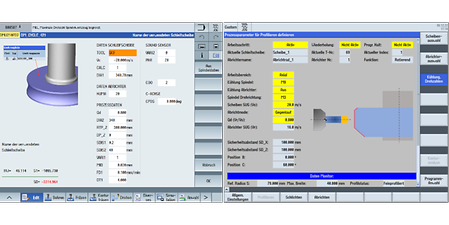

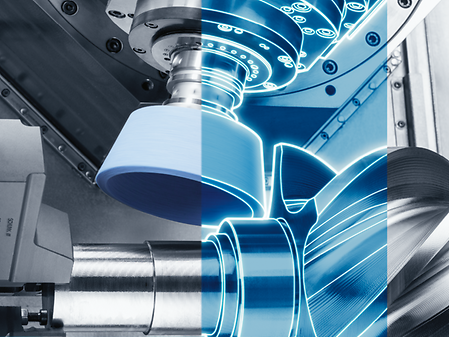

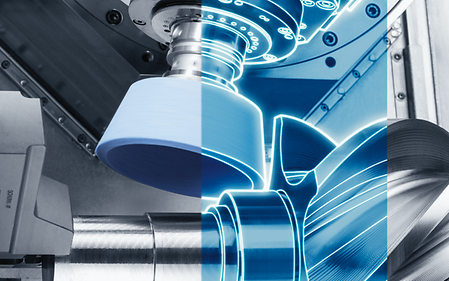

Flat Grinding

- Technology integration flat grinding on standard machines for best surface results

- Possibility of straightness compensation by definition of calibration points

- Acoustic emission sensor assisted approaching cycle

- ECS nozzle unit for best possible flushing of the grinding gap optionally available

Highlights

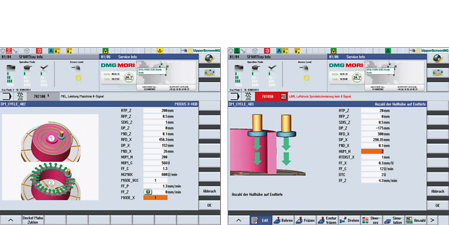

Interpolation turning 2.0 – turning recessing cycle

- With interpolation turning, the tool cutter follows a circular movement, where the cutter is always oriented towards the center Of the circle.

- Possible for external and internal machining

- Synchronization and tool path controlled by the cycle

- NEW: in version 2.0 complex turning contours are possible (currently only available on the DMU 50, other machine types will follow)

Highlights

Customer benefits

- Easy manufacturing of sealing surfaces where milling operation might not be possible.

- Complete component processing in one clamping possible

- Reduced investment costs for tools

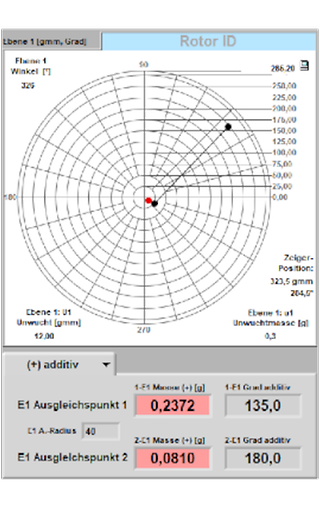

In-Machine Tool Balancing

- Balancing of tools in the machine for high surface requirements and machine protection

- Checking the balancing quality of the spindle

- Balancing quality up to 0.3 g/mm

Highlights

Customer benefits

- Better surfaces due to balancing of the entire system in the clamped state

- Balancing of the tool under machining conditions (machining position -vertical / horizontal, with / without internal cooling supply, speed)

- Economical, as no external balancing device is required

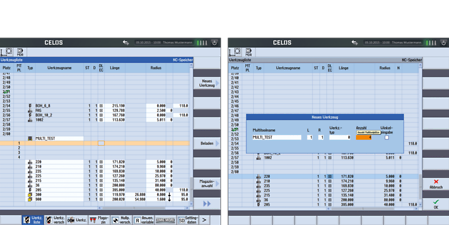

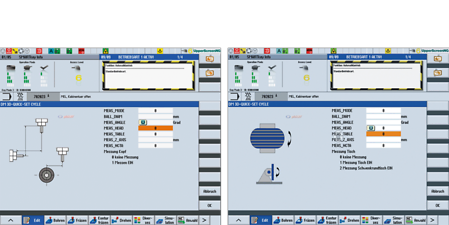

Efficient Production Package

- Solutions for a safe process and for the efficient use of important machining steps

- Applications: cone cleaning, tool data monitoring, safe withdrawal movement, tapping, deep hole drilling, external thread and spigot milling, internal thread and circular milling, reverse countersink cycle

- 12 stored machining strategies for stock removal, deep hole drilling, Pocket milling machines*

Highlights

Customer Benefits

- Runtime optimization according to individual application

- Safe retraction after program break

- Tool data monitoring

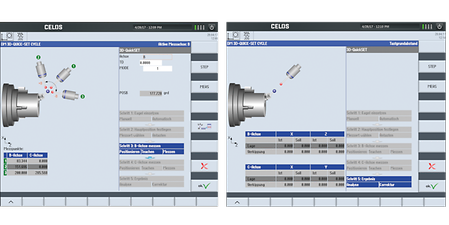

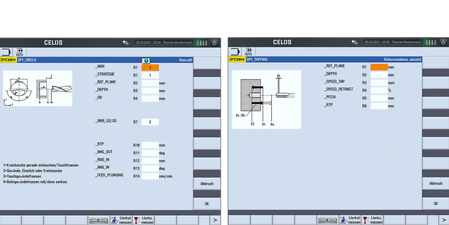

Left : Input mask for universal cycle pocket milling. / Right : Input mask for tapping cycle

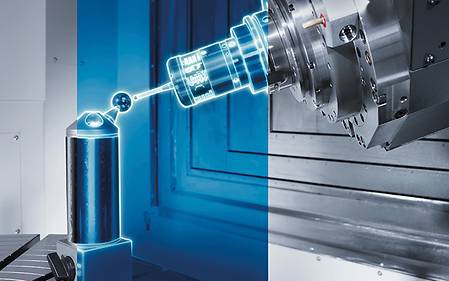

L-Measuring probe packet

- Measurement of webs and grooves on components

- Measurement of diameter in difficult to access places

- Available with manual and retractable Calibration unit Package content

- L-Measuring probe according to Customer-specific design

Highlights

Customer Benefits

- Flexible application possibilities

- In process measurement

Left : Semi-automatic Measurement solution. / Right : Automatic measurement solution.

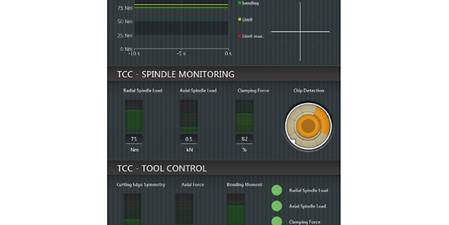

TCC – Tool Control Center

- Chip detection on plan pad and tool cone

- Monitoring of pull-in force

- Cutting edge control in process by symmetry monitoring of the bending moment per cutting edge

- Visualization of the bending moment over time via Graph

Highlights

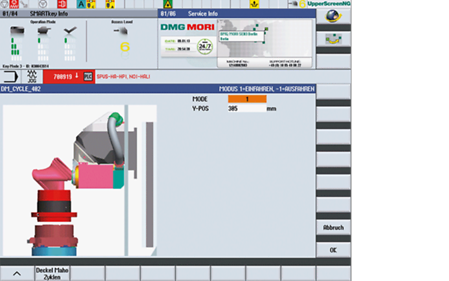

Fit in – B-axis Plunging

- Full utilization of the working space during internal machining of high workpieces with long tools

- Positional changes of the B axis during the turning are balanced by the X and Y axes

- The Z-axis remains at the retracted position while the B axis is moving

Highlights

Customer Benefits

Inner and outer travel of the B-axis.

- Easy programming

- Collision-free plunging in the workpiece

- Safely coming out from the workpiece after machining

angularTOOL

- Highest flexibility in the machining of structural components due to variable alignment of the angle head

- Automatic CAD / CAM programming

- Automatic calculation of the TCP and combination with existing control functions

Highlights

Profile Dressing

- Dressing of a profile on the grinding wheel by means of driven profile rollers (negative)

- Full utilization of AE sensor and integrated dressing strategies

- High time saving as well as high dressing accuracy due to customized dressing wheel development

Highlights

Customer benefits

- Tool and workpiece protection

- Optimized tool process

- Monitoring of the radial and axial spindle load depending on the actual pull-in force

Left: Parameterised input for the production of profiles; Right: Dialogue-guided contour dressing cycle

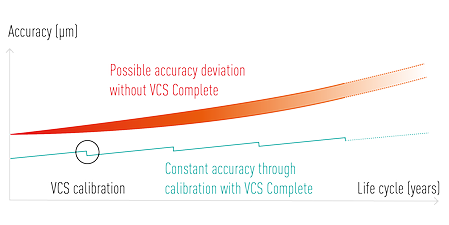

VCS Complete

- Geometric fingerprint of the machine Volumetric calibration at the touch of a button

- Detection and compensation of geometrical, positioning and angular errors of all axes

- Easy handling and implementation by the customer directly at the machine

Highlights

Tilted Measuring Cycle

- Measuring with tilted tool axis

- Dialog-guided programming of the measuring cycles

- Positioning of the measuring points with rotary axis

Highlights

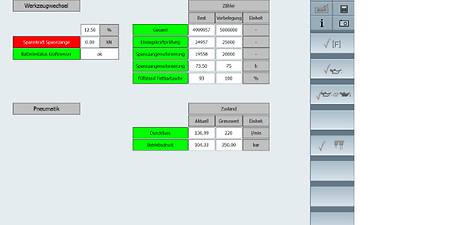

Maintenance Package i4.0

- Automatic recognition of tool pull-in force for consistently high process stability.

- Predefined cycle for automatic lubrication, every 75h or after 20,000 tool changes.

- Detection of leakage and measuring of usage of pneumatics system.

Highlights

Customer Benefits

- Efficient and timesaving lubrication without operator intervention

- High transparency by displaying the lubrication cycles and the current pull-in force.

- Data recording in combination with the optionally available Condition Analyzer for additional analyzes of air consumption and changes of the pull-in force

Detection of leakage and measuring of usage of pneumatics system.

Simple query of the monitoring parameters and the current pull-in force.

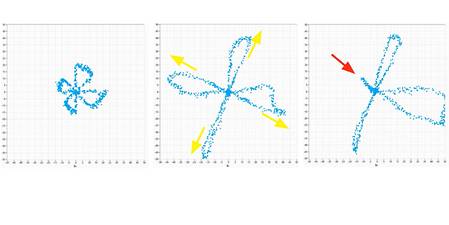

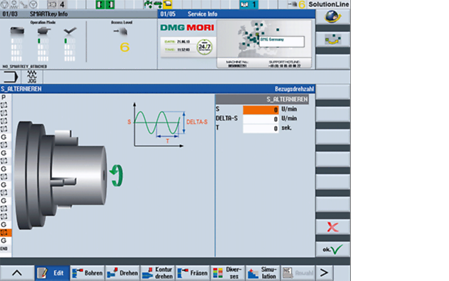

Alternating speed

- Easy to operate through three parameters and without additional sensors

- Avoiding vibrations by means adaptation of the speed

- Application for the main spindle and counter spindle, or for milling machines with FD tables with Direct Drive

Highlights

Customer Benefits

Input of parameters for speed set-point, differential speed and revolution frequency

- No manual intervention by the operator

- Identical repeatability for all components

- Increased process safety for special applications by avoiding vibrations. example, When using long thin drills or for milling parts with critical clamping

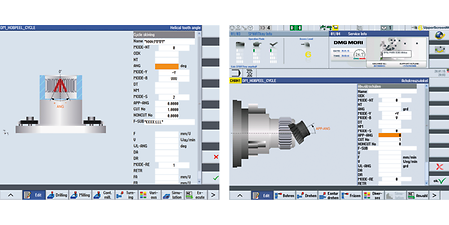

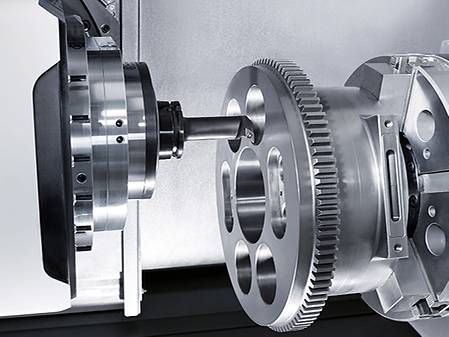

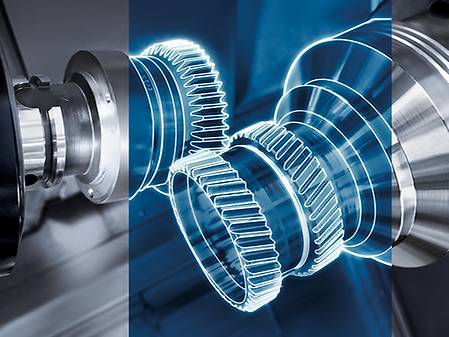

gearSKIVING 2.0

- Straight and helical external or internal spur gears and splines

- Arrow teeth with tooth offset Turn-mill machines

- Ball-shaped toothing by mathematical transformation of the 6th virtual axis

Highlights

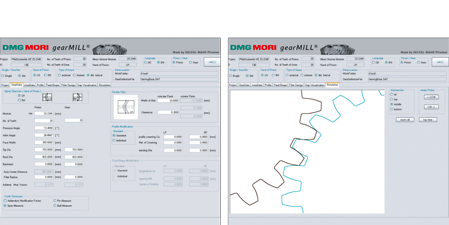

DMG MORI gearMILL

- Productive complete processing

- Cost-effective gear cutting on standard machine with standard tools

- Flexible for different gear geometries

- Quality inspection in the process

Highlights

Customer Benefits

- Program creation based on blank drawings and gear data

- Optimization of workpiece orientation e.g. after heat treatment

- Interface for coordinate measuring device (Klingenberg, Leitz, Zeiss)

Left : Input of the gear parameters for the geometry calculation of a spur gear. / Right : Grafische Betrachtung des Abwälzverfahrens.

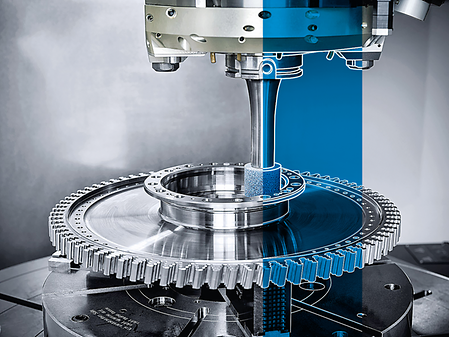

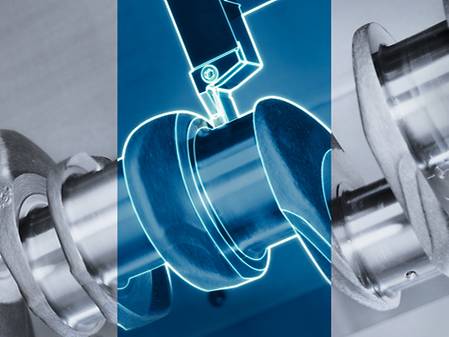

Grinding

Turning

- Turning, milling and grinding in one clamping

- Grinding cycles for internal, external and face grinding as well as dressing cyclesn

- Body-borne sound sensors for start-up and dressing

- Full integration of measurement module for relative and absolute LIVE-Measuring – parallel to main time

Milling

- Better surface quality through integration of the grinding technology

- Grinding cycles for internal, external and face grinding as well as dressing cycles

- Body-borne sound sensors for start-up and dressingn

- 1,300 l Cooling system with integrated centrifugal filter for The filtration of particles > 10 μ

- AKZ nozzle unit optionally available for best possible Flushing of the grinding gap

Highlights

Turning Customer Benefits

- Expansion of the technological limits of the CTX TC

- Surface accuracy < 0.4 μm

- Roundness < 5 μm

- Quality IT5 for ø > 30 mm

Milling Customer Benefits

- Surface accuracy < 0.4 μ

- Roundness < 5 μ

- Quality 5 for ø < 120 mm

- Quality 4 for ø > 120 mm

Multitool

- Efficient use of multi-tip turning tools with more than one cutting edge on turn & mill

- Several "sister tools" on one main tool holder

Highlights

Customer Benefits

- Reduction of tool change times

- Saves tool magazine space

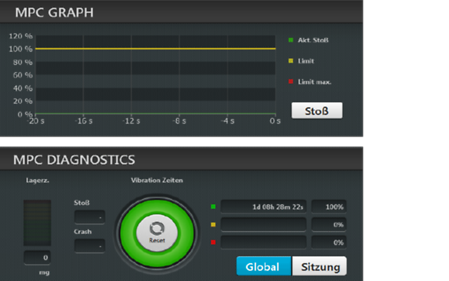

MPC 2.0 – Machine Protection Control

- Vibration monitoring in the process

- Rapid shutdown in case of a crash

- Manual retraction even in swiveled machining plane

- NEW: Torque monitoring

- New: Recommended with Protection Package for CTX TC machines

Highlights

Customer Benefits

MPC Graph: current and learned process values. / MPC Diagnostics: stock condition, number of impact and crash.

- Avoiding tool breakage

- Increase in machine availability

- Damage reduction

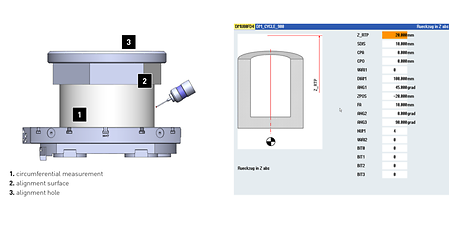

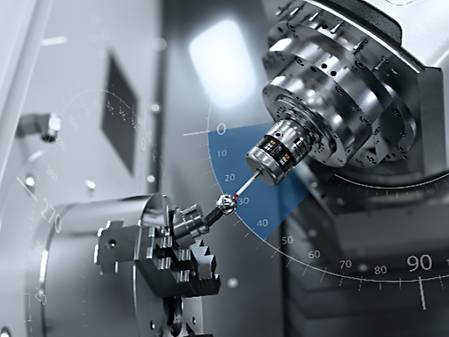

3D quickSET

Turning

- Measurement and correction of the position of turning and Pivot axes (C4, C3, B)

- Sag compensation possible

- Can be used in combination with standard probes from customers (recommended Renishaw, Blum)

Milling

- Toolkit for checking and correcting the kinematic accuracy of 4- and 5-axis machine configuration

- All head variations and table axes

Highlights

Turning Customer Benefits

- Reliable re-calibration of the machine before a highly precise processing

- Continuous documentation of machine accuracy

- No rejected parts due to unknown Geometric-deviations

Milling Customer Benefits

- Periodic recalibration of the machine with comprehensive documentation

- Highest kinematic accuracy in self-regulation

Define kinematics head

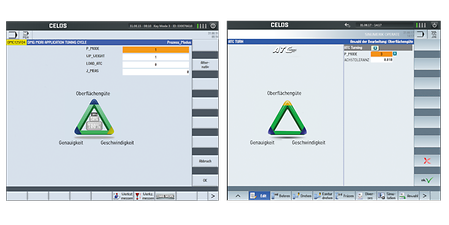

Application Tuning Cycle

- Process-oriented adjustment of the feed rate n relation to the table loading

- Minimization of machining time with maximization of the component quality

- NEW: Now also available for CTX TC. Ideal machining result with the highest machine dynamics*

*without consideration of feed weight

Highlights

Excentric turning and milling

- Superposition of the turning movement by additional X- and Y-traverses

- Applicable for turning and milling

Highlights

Customer Benefits

- Eccentric geometries easy to manufacture

- Exact axis coupling and synchronization in the background

Left : Enter the parameters for the position of the external workpiece area. / Right : Graphical representation of the position within the workpiece.

Service & Training

Downloads & Technical Data

Workpiece

Max. workpiece diameter

3,400 mm

Max. workpiece height

1,620 mm

Max. workpiece weight

9,000 kg

Max. workpiece weight (Type FD)

6,000 kg

Work Area

Max. X-axis stroke

2,700 mm

Max. Y-axis stroke

2,700 mm

Max. Z-axis stroke

1,600 mm